Discover Resources by Tags: wonder stuff

| Up a level |

Number of items: 6.

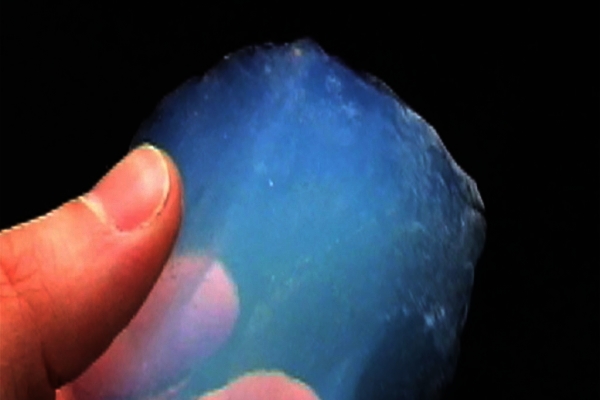

Aerogel

Shared with the World by Dr Zoe Laughlin

This is a rare sample of silica aerogel which is essentially a glass foam whose nano-structure contains up to 99.8% air, making it the world's lightest solid. It was made by Steve M. Jones, NASA Jet Propulsion Laboratory as part of the Stardust research project, which involved sending a spacecraft containing a large piece of aerogel on a close approach to the comet Wild 2 in order to collect space-dust. What made aerogel ideal for the mission was that, this ultra fine foam can gradually decelerate and capture dust particles in pristine condition. The process of then sifting through the aerogel, micron by micron, to identify and collect the space-dust was the world’s largest collaborative microscopy activity. The material appears to be much more invisible than glass despite being less transparent for there is no hint of reflection on its surfaces, giving it the appearance of not being fully solid. Its azure colour is not due to any pigmentation, but is caused by the same phenomenon that gives colour to our Earth's atmosphere, namely Raleigh scattering of light. In other words, it is blue for the same reasons that the sky is blue. Explore aerogel on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/aerogel.

Shared with the World by Dr Zoe Laughlin

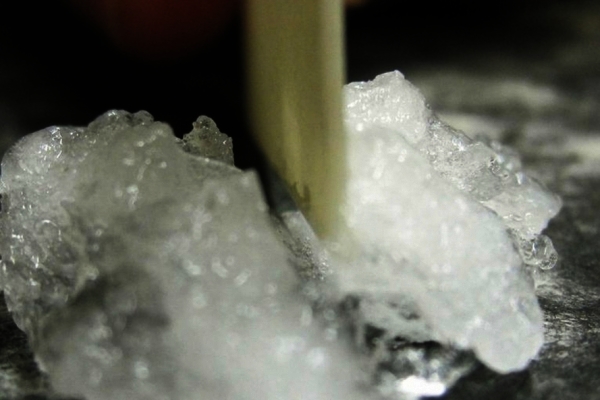

Aluminium nitride wafer

Shared with the World by Dr Zoe Laughlin

This thin fragile tile of ceramic material conducts the heat from your hand efficiently enough to cut through ice as if it were butter. Heat generated by the fingers is gathered from the two sides of the tile and conducted towards its edges, meaning that when an edge is placed against ice, the concentrated body heat melts the ice away. It is the speed of the conduction of heat that marks this ceramic out as a high performance material. If you hold it carefully between thumb and forefinger and then touch the edge onto you lip you will feel the rapid conduction of heat. Although the existence of this substance has been known of since 1862, it was not developed as a commercial product until the 1980s when its potential for use in electronics was recognised. Even then, early versions of this material were inconsistent. Although its performance has been greatly improved by technologists, its uses have thus far been fairly limited, largely to electronic and military applications, perhaps as a result of its high cost. Explore aluminium nitride wafer on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/aluminium-nitride-wafer.

Shared with the World by Dr Zoe Laughlin

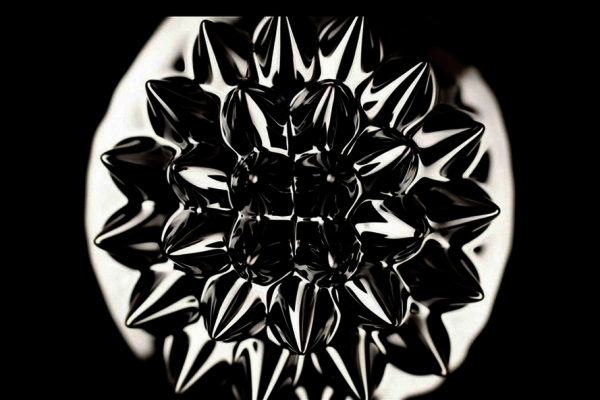

Ferro Fluid

Shared with the World by Dr Zoe Laughlin

On first inspection ferro fluid is easily mistakable for oil, given its dark colouration and ability to flow. But when placed in a magnetic field, it becomes a gel and forms complex geometrical patterns that reflect the magnetic field lines. These rippling, intricate geometries take shape because ferro fluid is composed of 1) a liquid - typically an oil – which allows it to flow when there is no magnetic field, and 2) nanoparticles of iron oxide that align with a magnetic field to restrain the fluid flow. Ferro fluid is a mixture of solid and liquid using an emulsifier to ensure they mix together perfectly to achieve this unusual material behaviour. Ferro fluid was developed in collaboration with NASA in the 1960s to address the issue of moving fuels in zero gravity. Today it’s used in lubricants, as a seal in hard disks, and car suspensions. Ferro fluid also has a strong following of artists who apply its unique properties to generate unique shapes in their work. Explore ferro fluid on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/ferro-fluid.

Shared with the World by Dr Zoe Laughlin

Self-healing concrete

Shared with the World by Dr Zoe Laughlin

In the future we may be surrounded by concrete structures, which are able to self-heal cracks in their structure, with special bacteria doing the job for us. Tiny cracks in concrete do not necessarily affect structural integrity in the short term, but they do allow water and other chemicals to seep into the structure, which may cause big problems over time. Self-healing concrete has dormant bacteria and a food source (starch) embedded in the concrete. When a crack appears in the concrete, water seeps in and reactivates the bacteria. After they awaken, the bacteria eat their packed lunch and then conveniently excrete calcite, which heals the crack. The bacteria can survive dormant in the material for 50 years. Explore self-healing concrete on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/self-healing-concrete.

Shared with the World by Dr Zoe Laughlin

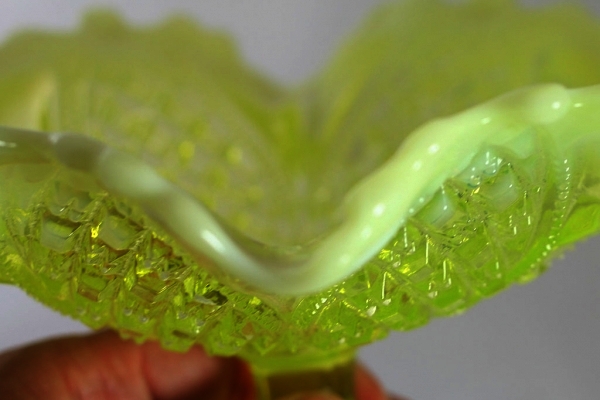

Uranium glass bowl

Shared with the World by Dr Zoe Laughlin

This glass bowl is made from sand containing uranium, which not only gives the glass its characteristic green colour, but makes it radioactive and strongly fluorescent. Uranium has long been used as a glass colourant, dating back to the first century AD. Uranium glassware was very popular in the early 20th century; however, production was curtailed when countries started conserving uranium supplies when the world entered the nuclear age during the Second World War. The rim of this particular bowl, which dates from around 1950 and comes from Australia, has been whitened by exposure to mercury. Explore uranium glass on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/uranium-glass-bowl.

Shared with the World by Dr Zoe Laughlin

![[img]](https://open-education-repository.ucl.ac.uk//307/2.hassmallThumbnailVersion/264_Image3-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//307/1.hassmallThumbnailVersion/264_Image4-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//316/1.hassmallThumbnailVersion/95.main-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//309/5.hassmallThumbnailVersion/ferro.1-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//309/1.hassmallThumbnailVersion/178.2-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//313/1.hassmallThumbnailVersion/060-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//313/2.hassmallThumbnailVersion/062-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//311/1.hassmallThumbnailVersion/303.main-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//311/2.hassmallThumbnailVersion/303_Image1-600x400.jpg)